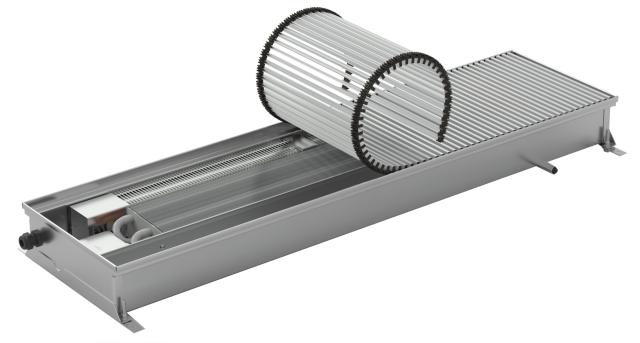

KORAFLEX Pool-V FVP

pool design

KORAFLEX Pool-V FVP heaters are suitable for heating humid environments (eg. swimming pools, conservatories, etc.). They are manufactured from AISI 316 stainless steel and are fitted with built-in drainage and dividing partition to protect against flooding. They are characterized by silent operation and can be connected to BMS (Building Management System). We recommend fitting an aluminium grille, and strict adherence to installation and operating guidelines. KORAFLEX Pool-V is finished with a hem, frams are not available.

EXCLUSIVE - RAL 9006 gray lacquered AL/Cu heat exchanger

Not suitable for installation in salt-water pools.

- Higher performance

- Low energy consumption

- Pool solution

- Heat pump synergy

| Depth [mm] | 110 mm |

| Width [mm] | 320 mm |

| Length [mm] | 800 up to 3000 mm (by 200 mm) |

| Heat output [W] | from 90 to 7 013 W |

| Max. Operating pressure [MPa] | 1.2 MPa |

| Max. Operating temperature [°C] | 90 °C |

| Connecting thread | inner G 1/2" |

| Casing material | AISI 316 stainless steel |

| IP rating | IP 20 |

| Cover grilles | |

| Individual KORAFLEX Pool heater casings cannot be combined, into multiple trench heaters and are manufactured solely as P0 and L0 models. Where a linear grille is selected, technical consultation is necessary, as the casing may need to undergo alteration. Please note, that linear grilles must be ordered together with trench heaters. |

ORDERING CODES

Example of ordering code: FVP-100/11/32-V6P0P0R-RT

KORAFLEX trench heater with fan (forced convection), Pool model, length 100 cm, depth 11 cm, width 32 cm, counter-flow RAL 9006 gray lacquered heat exchanger, finished with hem, right-hand connection, without lowered side, for roll-up grille, with 24 V DC regulation.

| KORAFLEX | Forced convection | Pool | | Length/Depth/Width (cm) | | Heat exchanger type | Heat exchanger colour | Frame | Frame colour | Connection side | Lowered face | For grille | | Regulation |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| F | V | P | - | 100/11/32 | - | V | 6 | P | 0 | P | 0 | R | - | RT |

| | | | | | | V counter-flow | 6 RAL 9006 9 other colour RAL | P hem | 0 without frame | P right L left | 0 without lowered face | R roll-up L* linear | | RT 24V DC regulation |

L* – technical alterations to convector casing

Contact us

For more information, do not hesitate to contact us