KORABASE

HEAT EXCHANGERS

The heat exchanger is at the heart of every convector. However, it has a much broader range of applications. Imagine that you want your heating units to blend in almost completely with the interior. Install the heat exchangers in the materials from which the entire interior is made.

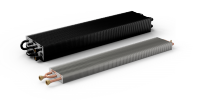

KORABASE heat exchangers with low water content are ideal for individual installations where there is a requirement for uniformity of materials used in the interior design. Working within a number of principles it is feasible to cover KORABASE heat exchangers with practically any material in order for them to merge into the interior. Heat exchangers are manufactured from copper tubes and aluminium fins.

| KORABASE Economic | Non-lacquered Al/Cu heat exchanger |

| KORABASE Exclusive | Black (RAL9005) lacquered heat exchanger |

| Height [mm] | 50, 100 |

| Width [mm] | 50, 100, 150, 200 |

| Length [mm] | 800, 1 000, 1 200, 1 400, 1 600, 1 800, 2 000, 2 200,2 400, 2 600, 2 800, 3 000 |

| Output [W] | subject to heat exchanger cover height: see ouput tables and correction factors for box heights |

| Maximum operating pressure [MPa] | 1,2 MPa |

| Maximum operating temperature [°C] | 90 °C |

| Connecting thread | inner G 1/2" |

| ΔT = 50 °C | Length [mm] | Temperature exponent | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Width [mm] | Height [mm] | Product | 800 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 | 2200 | 2400 | 2600 | 2800 | 3000 | |

| 50 | 50 | BP 11 | 222 | 285 | 348 | 411 | 475 | 538 | 601 | 664 | 727 | 790 | 853 | 917 | 1,3452 |

| 100 | 50 | BV/BP 21 | 478 | 613 | 748 | 883 | 1019 | 1154 | 1289 | 1424 | 1559 | 1695 | 1830 | 1965 | 1,3162 |

| 100 | 100 | BV/BP 22 | 622 | 800 | 979 | 1158 | 1337 | 1516 | 1695 | 1874 | 2052 | 2231 | 2410 | 2589 | 1,4151 |

| 150 | 50 | BV/BP 31 | 669 | 870 | 1070 | 1271 | 1471 | 1672 | 1872 | 2073 | 2273 | 2473 | 2674 | 2874 | 1,3176 |

| 150 | 100 | BV/BP 32 | 969 | 1248 | 1526 | 1805 | 2084 | 2363 | 2641 | 2920 | 3199 | 3478 | 3757 | 4035 | 1,4262 |

| 200 | 50 | BV/BP 41 | 989 | 1274 | 1558 | 1843 | 2128 | 2412 | 2697 | 2981 | 3266 | 3551 | 3835 | 4120 | 1,2735 |

| 200 | 100 | BV/BP 42 | 1314 | 1692 | 2070 | 2448 | 2826 | 3204 | 3582 | 3961 | 4339 | 4717 | 5095 | 5473 | 1,4137 |

|

| Standard supply content

Optional accessorieswall and floor brackets for mounting heat exchanger LIST OF BRACKETS KORABASE Exclusive version |

The air inlet surface is the flow area of the exchanger (width × length of the heating unit) minus the area of the exhaust grille (all measurements shown in %). The output of the given convector is multiplied by the correction factor. Outputs of heat exchangers are measured including the exhaust grille, and so it is not necessary to convert them further.

Contact form

For more information, don't hesitate to contact us.